The Pipemaster

The Pipemaster

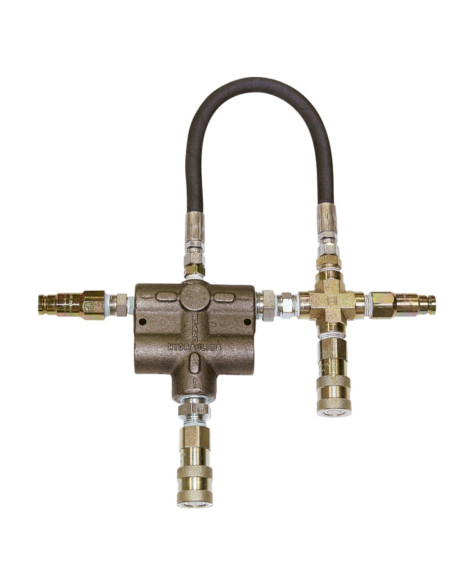

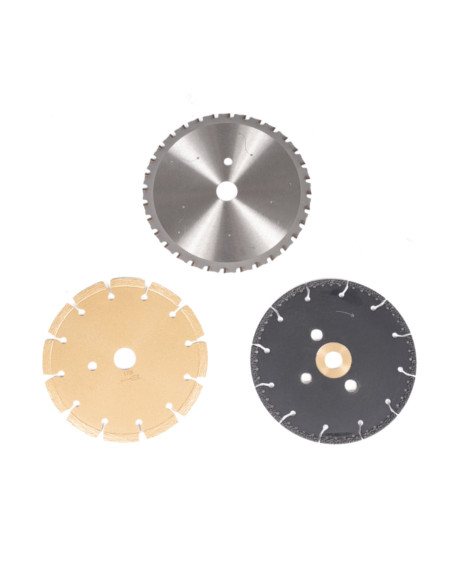

Unit consists of a cutting head with internal gears which operate the drive wheels and blade shaft. Cutting blades (except for No. 4616) must be cooled with water during cutting and are fully enclosed for safety. The cutter is held onto the pipe by a wide roller chain which is tensioned with a threaded take-up mechanism. A chart is included which tells the operator how much chain is required for various sizes of pipe. PipeMaster comes standard with cutting head, roller chain, wedges and water supply tank in a wood case. Blades are chosen based on pipe material and are not included with the basic machine. Maximum wall thickness for cutting is 1". The unit has a hydraulic motor which requires an external hydraulic power source.

PipeMaster Features

- Maximum hydraulic requirements 6 gpm/1500 psi

- Gearbox: Worm Drive with 80–90W gear oil required

- Cutting speed:

3" (150mm) of surface travel per minute

1" (25mm) of diameter per minute - Cutting Clearance: Radial 8" (200mm); Axial 16" (400mm)

- Blade Speed: 1200 RPM

- Construction: Aluminum gearbox, side plated steel; bronze gears, steel roller chain, drive wheels are aluminum with urethane covering

Specifications

- 5624 PipeMaster 6" to 24" (150–600mm) - Shipping weight 104 lbs. (47kg)

- Maximum hydraulic requirements 6 gpm/1500 psi

- Gearbox: Worm Drive with 80–90W gear oil required

- Cutting speed: 3" (150mm) of surface travel per minute 1" (25mm) of diameter per minute

- Cutting Clearance: Radial 8" (200mm); Axial 16" (400mm)

- Blade Speed: 1200 RPM

- Construction: Aluminum gearbox, side plated steel; bronze gears, steel roller chain, drive wheels are aluminum with urethane covering

- Cutting 30" pipe and larger may require special instructions to complete the cut.